Above, slab poured in the south addition.

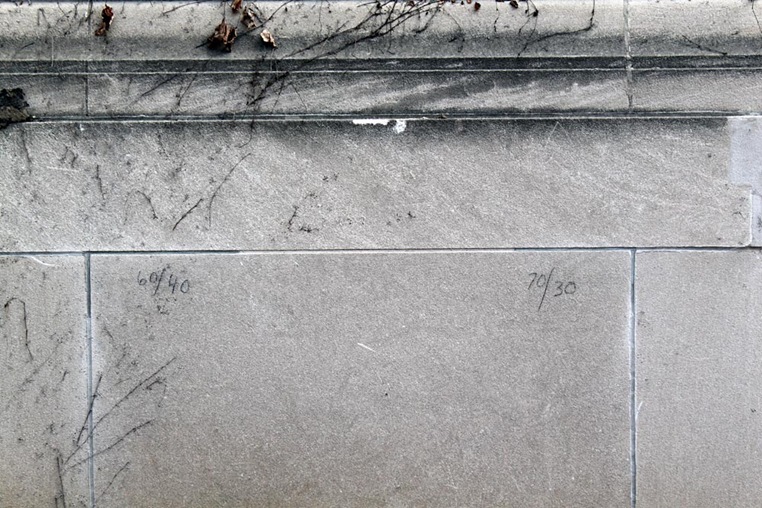

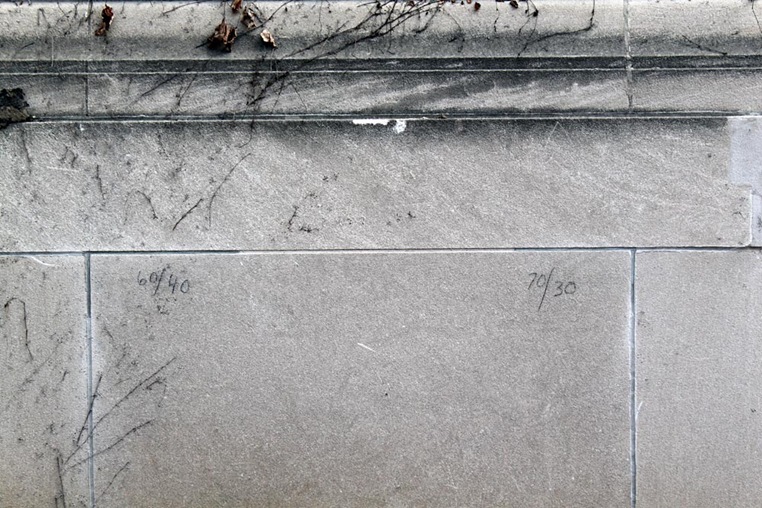

Two photos above: Matching the original mortar has proven to be a challenge.

Cutting with a torch on the third floor.

Looking through the open roof at University Hall. A view that will not be seen again in our life time.

A “Lull,” which is also known as a “high lift” is essentially a heavy duty, rubber tired, telescoping fork lift that can lift 6,000 lbs. to 42 feet high. The rubber tires and it’s weight allow it to maneuver easily in the deep mud that surrounds Harris Hall. Technically, it’s called a “telehandler.” Manufacturer’s photo below shows the stabilizers extended. (note: It costs more than a BMW).

Chargers everywhere underscore the reliance on batteries for power tools.

“Shoring” supports the freshly poured concrete slab that tops the south addition. This photo is taken in what will be the Center for Historical Studies.

Sly portrait of Don McDougal II, Turner Project Manager.

Sly portrait of Ron McAllister, Turner Superintendent.

Scaffolding has been erected on the east side of Harris Hall to facilitate masonry restoration.

The Lull looks like a toy from above.

Looking at the new addition from the southeast corner.

Standing (up high) in what will be the Graduate Student Lounge, looking west toward one of the classrooms.

One office has been drywalled and will serve to mock up shelving, wood trim, etc.